Liquid turbine meters

Description

We developed our first flow meter for oilfield applications in 1957. The meter incorporated a tungsten carbide shaft and bearing to withstand the adverse conditions of the oilfield environment. Over the years, this flow meter has built an unbeatable reputation for withstanding severe penalties while maintaining operational and Measurement integrity.The liquid turbine flowmeters of standard NUFLO LT pipeline indicate the flow rate and measure the total efficiency of a liquid line. As the liquid flows through the meter and over the rotor, the rotor rotates at a speed that is directly proportional to the flow rate. A magnetic pickup detects the rotor blades as they pass and generates an electrical signal (sine wave). These electrical pulses are then transmitted to the Flow Measurement reading device.

Standar Caracteristics

Terminate connections

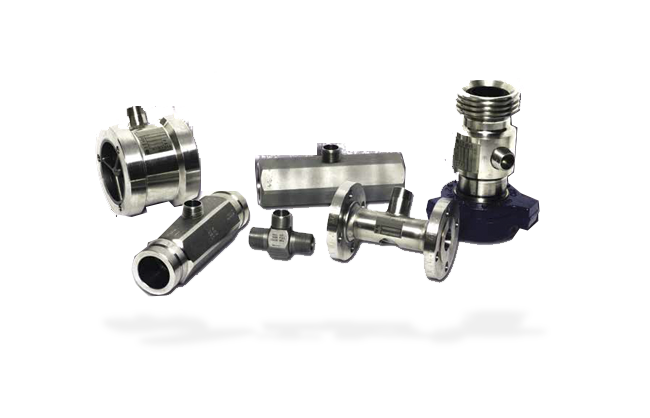

Cameron offers turbine flow meters in a variety of final connections and accuracy levels. Typical applications are:

Threading

Striated

Beading

EZ-IN

WECO 1502

Flanged end connection

Turbine flow meters with flanged end connections are available in both high face (RF) and ring joint (RTJ) models. Flanged materials can be carbon steel or stainless steel. All liquid turbine flowmeters with NUFLO flanges are equipped with sliding flanges, which are then welded to the outside of the meter instead of being welded to the end of the meter body. Therefore, the flange never comes into contact with the fluid that is being measured. The flanges are designed to be coupled with ANSI B16.5 flanges.

Slotted end connection

Flowmeters with slotted end connections are available in sizes from 7/8 "to 8".

Cameron offers turbine flow meters in a variety of final connections and accuracy levels. Typical applications are:

Slotted end connection

Flowmeters with slotted end connections are available in sizes from 7/8 "to 8".

Final connection EZ-IN

Turbine flow meters of the BF series with EZ-IN connections provide an economical alternative to typical applications of flanged meters. BF Series meters with EZ-IN connections offer the precision, rugged construction and maintenance-free operation of conventional NUFLO flow meters plus the following advantages:

Lower installation cost

Less expensive than a conventional flanged meter

Spreader nuts allow easy removal and inspection

The high face EZ-IN meter will be attached to any flange rated ANSI 150 # to 1500 #. The annular joint version (RTJ) will be attached to ANSI 900 #, 1500 # or 2500 # RTJ flanges (specify the type of flange when ordering)

The 8 "x 8" EZ-IN RF with CE marking requires special centering rings WECO 1502 Union End Connection

Flow meters with 1502 end connections are commonly used in high-pressure oil well service applications. The 1 ", 1-1 / 2" and 2 "meter sizes have final 2" union connections with a wing nut on one end and thread on the other end. 3 "meters have final 3" union connections with the option of a wing nut on one end and threaded on the other, or threads on both ends. All NUFLO WECO 1502 union meters have two collection adapters.

Turbine flow meters of the BF series with EZ-IN connections provide an economical alternative to typical applications of flanged meters. BF Series meters with EZ-IN connections offer the precision, rugged construction and maintenance-free operation of conventional NUFLO flow meters plus the following advantages: