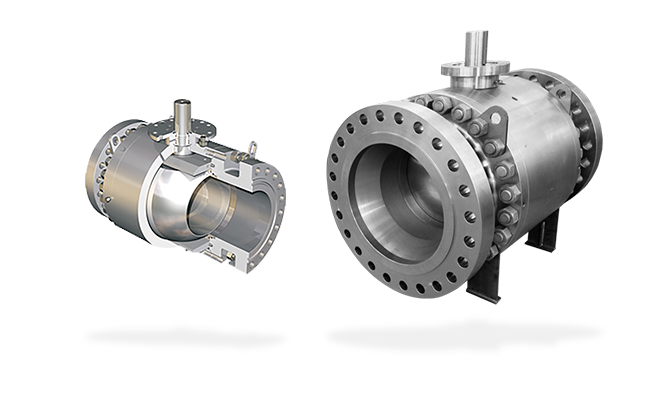

Ball Valve CAMERON

Description

CAMERON GROVE are manufactured in a wide range of diameters and pressure classes. Valves are specified for transmission, pumping, compression and reinjection units, marine platforms, land terminals, tool traps and Measurement stations. The construction of Split-Body "body three pieces" allows the use of forged materials in the different qualities of carbon steel, stainless steel and high alloys, for more severe service, heavy duty, low maintenance, designed for high pressures, temperatures and tensions.The fully welded ball valves of the T30 series from CAMERON meet ANSI standards 150 to 2500 and API 2000 to 10,000. Manufactured in forged steel to ensure uniform fine grain structure and hardness, they can be specified in sizes from 2 to 56 in. [50 to 1400 mm].

Valve Details:

Brand: CAMERON GROVE

Sizes: Since 6 “ to 64”.

ISO : Fire safety according to API 6FA and BS 6755 Part II

Clases: ASME: 150 to 1500.

Technical specifications

Design mounted on stump.

Double barrier stem seals and emergency tap for springs.

Stem separated from the ball and anti-burst design of the stem.

Low friction PTFE thrust bearings and washers, with metal backing and self-lubricating.

Metal-to-metal main seal and protected secondary seal of O-ring.

Seat rings with double piston effect (DPE) (double sealing barrier in both directions).

Double blocking and bleeding capacity.

Valve pressure relief in the body cavity to prevent pressure blockage.

Sealant injection system for emergency sealing. External stops positioned at the factory.

Integral stop on the adapter plate for permanent reference to open and closed positions.

Electrolytic nickel coating on the parts and the pressure control stem.

CE Marking (PED Directive).

Optional caracteristics:

Triple barrier stem seals.

Self-relief seat rings.

Polymer plastic insert for sealing the seat.

PTFE lip seals for sealing the seat and the stem.

Sealed metal-to-metal seating.

SS or INCONEL® * 625 overlap in sealing areas.

Seals resistant to explosive decompression (standard for class 600 and above).

Anti-static device.

Fire safety according to API 607.